| Product Details: | |

|---|---|

| Model | 3D Mixer |

| Capacity | 3 ltr to 1000 ltr |

| Design Type | Standard, Customized |

| Max Mixing Mass (Kg) | 3kg to 1000kg |

| Motor Power (Hp) | 0.3 |

| Power Supply (V) | 220 |

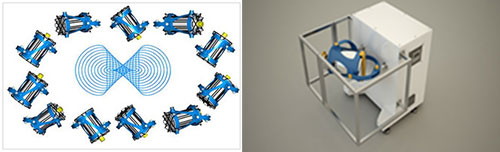

MIX THE IMPOSSIBLE TO PERFECTION

3D mixing (also known as Turbo mixer or Tumbler mixer) is most efficient & innovative technology for uniform / homogeneous mixing. It is used for powder / liquid / suspensions- irrespective of their proportion, density and partial size.

3 Dimension Shaker mixer is widely used for uniform mixing of Uranium powders. Uranium powders of different specific weights, sizes, or shapes can be blended to perfect uniformity. We offer models in 3, 10, 20, 35, 75 Ltr as standard models and larger model as per customer requirements.

3D Mixer is ideal for applications demanding blending for industries like – Metallurgy, Abrasives, Minerals, Metal powder, Food & Pharma, Bio science, Nano technology, Explosive material, Ceramics, Cement, Polymer, Photo chemistry and many more

Industry Application

Pharmaceuticals -Small amounts of potent drugs with large volumes of material

Powder Mixing -cobalt, Manganese and Copper with a silicate for fluidity

Diamond Tools -Mixing industrial diamonds with either a resin/metal matrix

Ceramics Mixing- glass batches including Silica, Alumina and other additives

Nuclear Industry- Mixing friable Uranium Dioxide granules

Explosives Mixing- Aluminum powders with explosive dusts

Pyrotechnics For -production of fireworks and signal rockets

Food Mixing of milk- protein powders for homogeneity

Cosmetics Mixing -constituents to coat particles with additives

Photo chemistry -Producing homogeneous mixtures of Silver Halogen crystals

Batteries -Blending of dry cell components

Plastics -Blending of pigments with resins, lubricants and other additives

Metal Finishing- DE-burring and polishing, without bending or damage.

Ball Milling -Grinding media in choice of material and size

Features Of our 3D Mixer

Suitable for different specific weight and particle size mixing

No product separation

No centrifugal force and local heating

Removable mixing drum

Specifications

Heavy powders with very light ones – Homogeneously

Minute quantities with huge volumes- In one step

Pharmaceuticals- With the highest degree of purity

Crumbly granulates- Without excessive fines

Toxic materials- In complete safety

Biological substances- Without heating

Benefits

* High Mixing efficiency

* Dust free hygienic mixing in closed container

* Short Mixing time

* No segregation of the different compounds

* Gentle mixing